Contact Us

Office Mob: +8615524105871

Office Tel: +86-024-31931990

Office Fax: +86-024-22845391

Email: info@eoexport.com

Whole Set of Fried Flour-Coated Peanut Production Line

Basic Info

Model NO.: YPHS-300

Power Source: Electric

Application: Candy

Name: Fried Flour-Coated Peanut Machine

Raw Material: Peanut Kernel

Matched Machines: Roaster, Mixer, Coating, Frying, Deoiling, Seasoning

Operation Manual: Can Be Supplied

Trademark: HYPH

Specification: one 20GP container

HS Code: 8422400000

Certification: CE, ISO9001

Automatic Grade: Automatic

Customized: Customized

Capacity: 200-300kg/H

Final Product: Japan Peanut Bean, Fishskin Peanut Bean

Usage: Snack Food

Working Video: Can Be Supplied

Transport Package: Wooden Case or Nude Pack

Origin: Made in China

Product Description

Whole Set of Fried Flour-Coated Peanut Production Line

Coated peanut,cocoa bean,Korea bean,it is made mainly by peanut kernel with rich nutrition,coating seasoning powder,seasoning flavor with outer,mature technology,high mechanical degree,easy operation.

Technology process for whole set of fried flour-coated peanut plant

Roasted peanut kernel-coating-mixing powder-mixing multi layer coating-frying-seasoning-cooling-final product

The equipment can produce Japan bean,coated peanut,aromatic core etc.

1. roaster machine

MHK series multi-functional rotary roaster is suitable to roast and dry peanuts,sesame, peanut kernel, cashew, chestnut,walnut, almond, swallow bean, cocoa beans, melon seeds and so on. Our machine is heated by electricity, fuel, gas and coal. Adopting rotary drum, heat conduction, thermal radiation principles, heated by coal can decrease cost(roasted material doesn't contact with the fire). Convenient to use, high efficiency and energy saving, durable, high quality roasted products, healthy, tasting best, it also can reach the exporting standard.

2. mixing machine

The barrel is round design, inner screw blade,make ready-process food material fully mix with needed season,twisted mixing,reverse running take out of the barrel.automatic mixing,automatic discharging.The machine can process Japan bean,coated bean,aromatic core etc

3. coating machine

Water chestnut type coating machine mainly used in coating press formed slice,pill and pellet for pharmacy industry,also used in food process or coating.

Sugar coated tablet after coating and polishing with smooth surface,which can prevent from oxidation,damp or volatile,also cover the discomfort taste,make the drug easy to identify and relax the dissolution in the human intestine and stomach.

The frequency control of main motor is driven by V-belt,worm and worm wheel reducer can make vessel get reasonable speed,vessel run stable,can lock by itself.

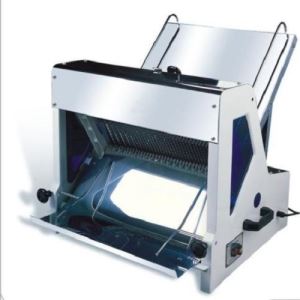

4.fryer machine

The fuel can be coal,electricity,gas,oil etc,adopts oil-oil mixture,middle heating,upper frying place in high temperature,down in low temperature structure,save energy 50%, save oil 40%,oil will not become black for long time,waste residue can be cleaned on time,change the old structure with bottom heating,avoid the abuse of old fryer machine.

5. centrifuge deoiling machine

Made by full stainless steel,electromagnetic brake,digital control,the most advanced deoiling equipment for fried food.

The fried food deoiling machine is used for fried food deoiling,deoiled product with nice color,oil can be used again.It adopts centrifuge force working principle,second deoiling for the food out of fry-pan, develop the quality of deoiled product,save the cost.

6.seasoning machine

Easy operation,large capacity,drum body made by full stainless steel.

Drum design is octagon,avoid that round seasoning drum materials do not turn over, can make ready process food materials mix uniform with needed season,automatic lean to send food materials out of drum.Automatic mixing uniform,automatic discharge,this series equipment can produce Japan bean,fishskin bean,crisp fruit,mouthful sweet,dinosaur egg,shrimp fried bean,spicy bean etc.

Previous: Stainless Chocolate Fountain

Related News

- 80-100kg/H Capacity High Quality Do...

- Steamed Stuffed Bun Making Machine

- 7 Tiers Commercial Chocolate Founta...

- Candy Type Automatic Feeding Packin...

- Chocolate Fountains

- Low Price Chocolate Fountain Machin...

- Espresso Maker, Coffee Machine (CM-...

- 6 Six Tiers Stainless Steel Chocola...

- 4 Tiers Stainless Steel Chocolate F...

- Stainless Chocolate Fountain

- Puffing Snacks Food Production Line

- Ce Standard Full Automatic Popcorn ...

- Features & Advantages Of Stainless ...

- Automatic Stainless Steel Hand Dump...

- Features & Advantages Of EO Stainle...

- Stainless Steel Automatic Manual Gy...

- Quick Details Of EO Gyoza Machine

- Features & Advantages Of EO Stainle...

- Stainless Steel Automatic Manual Du...

- Newest Chinese Stainless Steel Baoz...

Second Floor, No.29 Shiyiwei Road, Heping Liaoning Shenyang.

Second Floor, No.29 Shiyiwei Road, Heping Liaoning Shenyang. +86-024-31931990

+86-024-31931990 +86-024-22845391

+86-024-22845391